Industrial Electrification: the Biggest Climate Solution You’ve Never Heard Of

Tackling industrial emissions is a fundamental step in solving climate change

You might have considered how the energy that powers your car or lights up your home can contribute to climate change. But what about the energy used to manufacture all the things you use, from the clothes you’re wearing to the device you’re reading this on?

Energy use pervades the economy, and the industrial sector is no exception: Over a third of the world’s energy goes towards manufacturing the physical products we rely on.

Like in other sectors, most of that energy currently takes the form of fossil fuels, which industry uses in two ways: as feedstocks that are chemically transformed into products and as energy to power industrial processes. Together, both uses make industry responsible for a third of the world’s greenhouse gas (GHG) emissions. However, using fossil fuels for energy creates most of those emissions—specifically, burning fossil fuels to heat industrial processes.

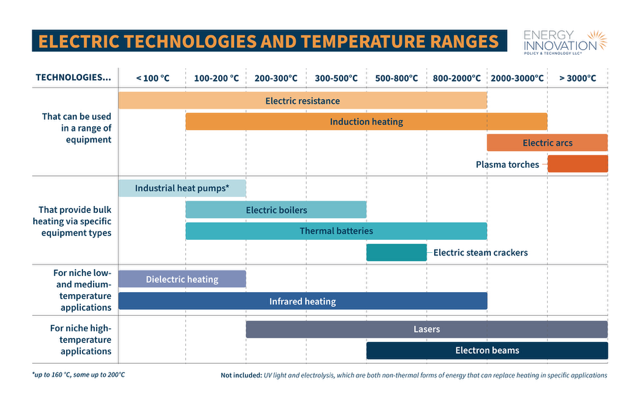

It doesn’t have to be that way, according to a new report from Energy Innovation. Fossil fuels aren’t the only source of industrial heat, whether it’s low-temperature heat (less than 200 °C) that dries paper and cooks food, medium temperature heat (200-500 °C) that distills chemicals and joins metal parts, or high-temperature heat (500-1800 °C) that smelts metal and melts glass.

Using proven technologies, electricity can provide heat at all temperatures industry uses today. Some of those technologies are already available on the market, like industrial heat pumps and electric boilers that create steam for a variety of processes. Others are showing promise in laboratories and in real-world pilots, including electric steam crackers that break down high-value chemicals and plasma torches that turn limestone into cement.

Electric technologies, powered by clean energy, are the single best way to cut emissions from industrial process heat. For one, direct electrification uses less energy than green hydrogen, which loses energy both when it’s produced and when it’s burned. Compared to bioenergy, electrification requires much less land and avoids tradeoffs like deforestation, ecosystem disruption, and competition with regional food and water sources. And compared to carbon capture and storage (CCS), electrification requires far less capital investment and avoids upstream emissions from fossil fuel extraction. To top it all off, powering industry with clean electricity keeps health-harming pollutants like nitrogen oxides and particulate matter out of the air, something that can’t be said for alternative solutions. Hydrogen, bioenergy, and CCS will have niche roles to play in decarbonizing industry, but electrification is the best option wherever it is technically possible.

Still, even after dispelling the hype for other solutions, the road to electrification is winding. Our report lays out three barriers to electrifying industry today: economics, grid readiness, and technology maturity.

First, it’s currently more expensive to power industrial processes with electricity than with fossil fuels, not only because electricity costs more than fossil fuels, but also because of utility interconnection and disconnection fees, the capital costs of replacing industrial equipment before it retires, and the soft costs of hiring and upskilling workers.

Second, utilities aren’t moving quickly enough or planning adequately enough to add clean energy to the grid, which is critical for a solution that add substantial electricity demand to the economy.

Third, as mentioned earlier, not all technologies to electrify industry are commercially available today, making certain options too expensive and risky for firms to adopt.

These barriers are no reason to shy away from electrifying industry. In fact, they demonstrate a clear policy pathway to enabling industrial electrification around the world. A wide range of policies can make electrified processes cost-competitive with conventional ones, from renewables deployment policies that cut electricity costs to government incentives for clean production. A variety of grid interconnection and planning reforms can prepare the grid for more electricity demand from industry, while policies like energy efficiency standards and utility rate designs that incentivize flexible energy use keep industry’s electricity demand manageable. And governments can help to commercialize electrified technologies with funding for research, development, and demonstration as well as incentives and standards that encourage technology development through real-world learning.

Our report is a designed to be a toolkit for policy makers who want to clean up their jurisdiction’s industry but aren’t sure where to start. It outlines the many policies that can overcome each barrier to electrifying industry, allowing decision makers to choose the suite of policies that fit their region’s political priorities and holistically overcome electrification’s obstacles. No one policy can clean up industry on its own, but the right mix of policies can drive real industrial transformation, creating a safer and more livable planet for generations to come.